WRAP CHAIR I

缠椅 I

用途 Function:

家具 FURNITURE

所在地 Location:

-

实施阶段 Phase:

制作完成 MADE

周期 Construction Period:

-

完成日 Complete Time:

2007

规模 Size:

-

建筑面积 Floor Area:

-

椅子的概念和它的物质现实

我们提出的既不是物质也不是概念的椅子,而是存在于两者之间的一种状态。作为观者,人们能从椅子的剖面形状找到建筑师对这一产品类型的概念的设想;而作

为体验者,椅子的实体随着身体的重量渐渐消失于椅子的结构之轻而被人们所感知。

线/面/体

类似于一件艺术品的制作,椅子的生产过程也经历着线/面/体的构成。而每个艺术创作的过程都与工业加工的过程息息相关:生产,分配与消费。

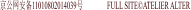

线

生产。按照模具文件中的指令,数控机床会对15mm和5mm胶合板进行二维切割。而对于人工部分,简单的后续打磨是唯一需要做的。数控机床的精度会使其避免在制造

过程中对材料剪切所造成的错误和浪费。

面

分配。在传统的胶合板加工工艺过程中,胶合板往往会容易变得弯曲。这使得在包装的过程中,浪费大量空间。由于胶合板可以在加工后仍然可以保持水平状态,这使得

15mm和5mm胶合板可以水平放置在彼此的顶部等待包装。而这则大大避免了由于胶合板弯曲造成的包装空间的浪费。归功于新的制造工艺,使得更多的产品可以被放置在同一

架飞机或货物集装箱。因而这也大大降低了对交通的需求,产品的成本也因此得到很好的控制。最为重要的是,由于大大降低了对交通的需求,不仅产品的成本得到了更好的控

制,它更为整个社会生态的环境做出了贡献。

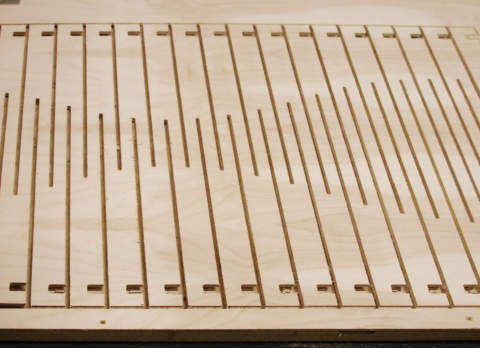

体:消费。当产品到达消费终端,消费者可以很容易地组装胶合板,并且不需要胶水或额外的工具。一个三维的椅子体积结构被轻易的创建。当两块15mm胶合板提供垂直

支撑时,一块5mm的胶合板悬垂直于两者之间,并缠绕着15mm的胶合板持续的提供水平方向上的支撑。较厚的胶合板用于承受压力,而相对于较薄的胶合板则用于承受张力。

由查尔斯和伊姆斯提出的:“弯曲胶合板的概念”,在数字化运用的时代,被重新解析和定义,并被推向了极致。

通过重新规划与设计椅子生产线的过程,我们创造的重点不再是椅子的样式,而是着重于定义作为椅子的其它重要属性。在这个椅子的设计里,椅子的制作是一个

全球化的过程。因此,椅子不再是简简单单供人休憩的一个小物体,在全球化的背景下,它俨然已经成为一个联系社会的至关环节,是当今时代的一个重要文化产物。

The concept of chair and the physical reality of it

The chair we proposed is neither an object nor a concept, but an in-between status of the two. One might find a conceptual depiction of a stereotypical chair in its

sectional profile. Yet, as observation angel changes slightly, the physical reality of the chair begins to emerge: one could feel the body, suspended in the light weight structure

of the chair.

Line—Surface—Volume

Similar to the making of an artwork, the production of the chair also goes through stages of line, surface and volume. Each of the artistic stage correlates with the

industrial stage: manufacture, distribution and consumption.

Line—manufacture

Following the lines prescribed in the tooling file, the CNC milling machine would make 2-Dimentional cuts on the 15mm and 5mm plywood sheets. The simple cuts are

the only thing needs to be done at the manufacture end. The precision of CNC would avoid mistake and waste of material in the manufacture process.

Surface—distribution

The plywood sheets remain flat after the CNC processing. The 15mm and 5mm plywood sheets could be placed right on top of each other for package. Unnecessary air

space is minimized in packaging. More products could be shipped on the same airplane or cargo container. Since there will be less transportation need, the cost of the product

would be saved tremendously. Also, it would be more ecological to the society as a whole.

Volume—consumption

As the product reaches the consumer end, consumer could easily assemble the three plywood sheets together without glue or extra tools. A 3-Dimentional volumetric

structure of the chair is created. While the two pieces of 15mm plywood provides vertical supports, the one piece of 5mm plywood suspended between the vertical supports

and wrapped around the edge of 15mm plywood to provide frequent horizontal bracing. While thick plywood works in compression, the thin one works in tension. The notion

of “bending plywood,” initiated by the design of Charles and Eames, is reinterpreted and pushed to the extreme with digital means.

Rather than inventing a new form of chair, the design revolutionizes the production line of the chair, thus defines a new type of chair. The making of the chair is

understood as a global process in the design. A chair is not only a chair, but a crucial link within the society, a culture artifact of our time.